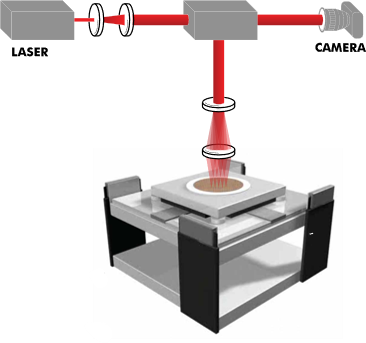

The LASER1205 has a unique system for inline vision, all camera and laser activities make use of the same optical system. This ensures a high accuracy and gives the opportunity for “On-the-Fly” monitoring of the wafer dicing/grooving process. The following activities are done through the same lens:

- Laser processing of the wafer.

- Calibration of the position of the laser spots.

- The alignment of the wafer.

- The “On-the-Fly” monitoring of wafer and kerf positions.

By using the same optical path there are no overlay errors between cutting and “On-the-Fly” monitoring of the wafer. Which is beneficial for the accuracy of the laser dicing process. Because of this unique system, ASMPT LASER1205 is the only system in the market that allows for real “On-the-Fly” inspection of processing position for wafer and kerf measurements.