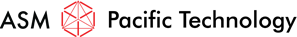

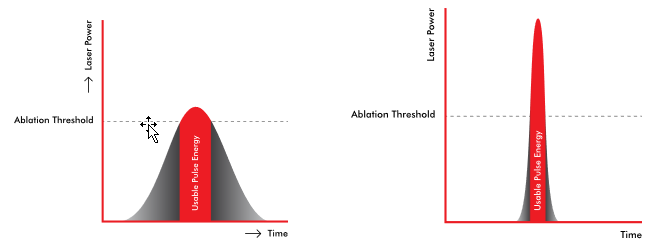

A laser produces light of a certain wavelength. The way the light energy comes out of the laser can be continuous or it can be pulsed meaning the light energy comes out in short duration of time. For a continuous laser the energy is constantly flowing into the material similar as a soldering iron. This means that a lot of energy inserted into the material can be conducted to the adjacent material and cause the whole material to heat up and therefore increases the HAZ. When using a short laser pulse to insert the energy into the material (<1us) the energy does not have time to conduct to adjacent areas and therefore all energy is used to remove material rather then to increase the HAZ in the adjacent material.

A laser produces light of a certain wavelength. The way the light energy comes out of the laser can be continuous or it can be pulsed meaning the light energy comes out in short duration of time. For a continuous laser the energy is constantly flowing into the material similar as a soldering iron. This means that a lot of energy inserted into the material can be conducted to the adjacent material and cause the whole material to heat up and therefore increases the HAZ. When using a short laser pulse to insert the energy into the material (<1us) the energy does not have time to conduct to adjacent areas and therefore all energy is used to remove material rather then to increase the HAZ in the adjacent material.

For ASMPT’s laser we typically use nanosecond lasers (10-9 sec) or femtosecond lasers (10-15s) which is also referred to as Ultra Short Pulse (USP). Each of these lasers has it own benefit and application area.

Nano second laser:

- Higher material removal rate which allows dicing of thicker wafers

- Less complex laser technology which makes it lower cost and maintenance

Ultra Short Pulse laser:

- Low HAZ and therefore higher die strength (typical >800MPa for 50um thick Si)

- Lower burr due to less thermal process behaviour.

- Lower material removal rate per pulse which limits thickness of wafers